1

/

of

5

Drill Bits Unlimted

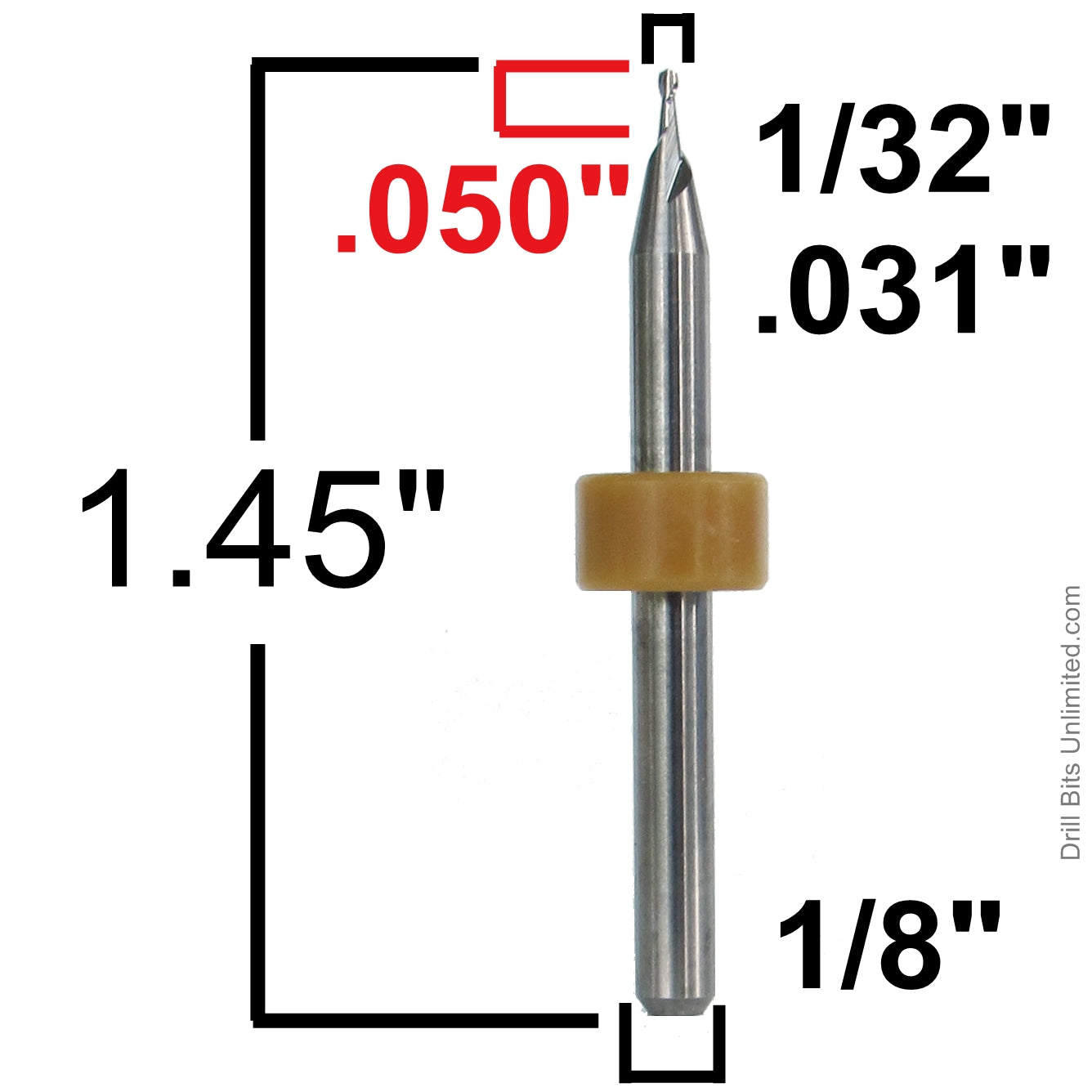

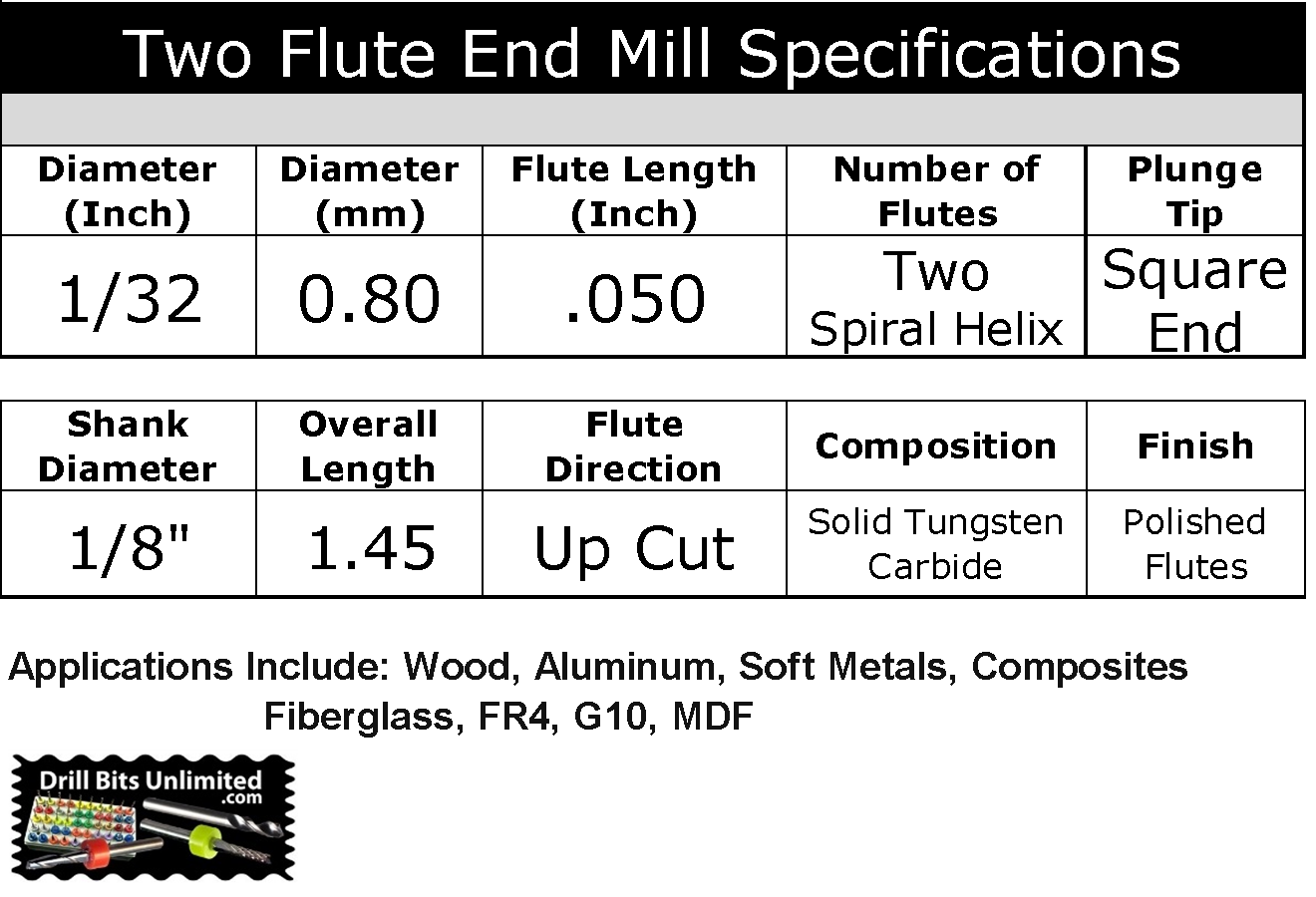

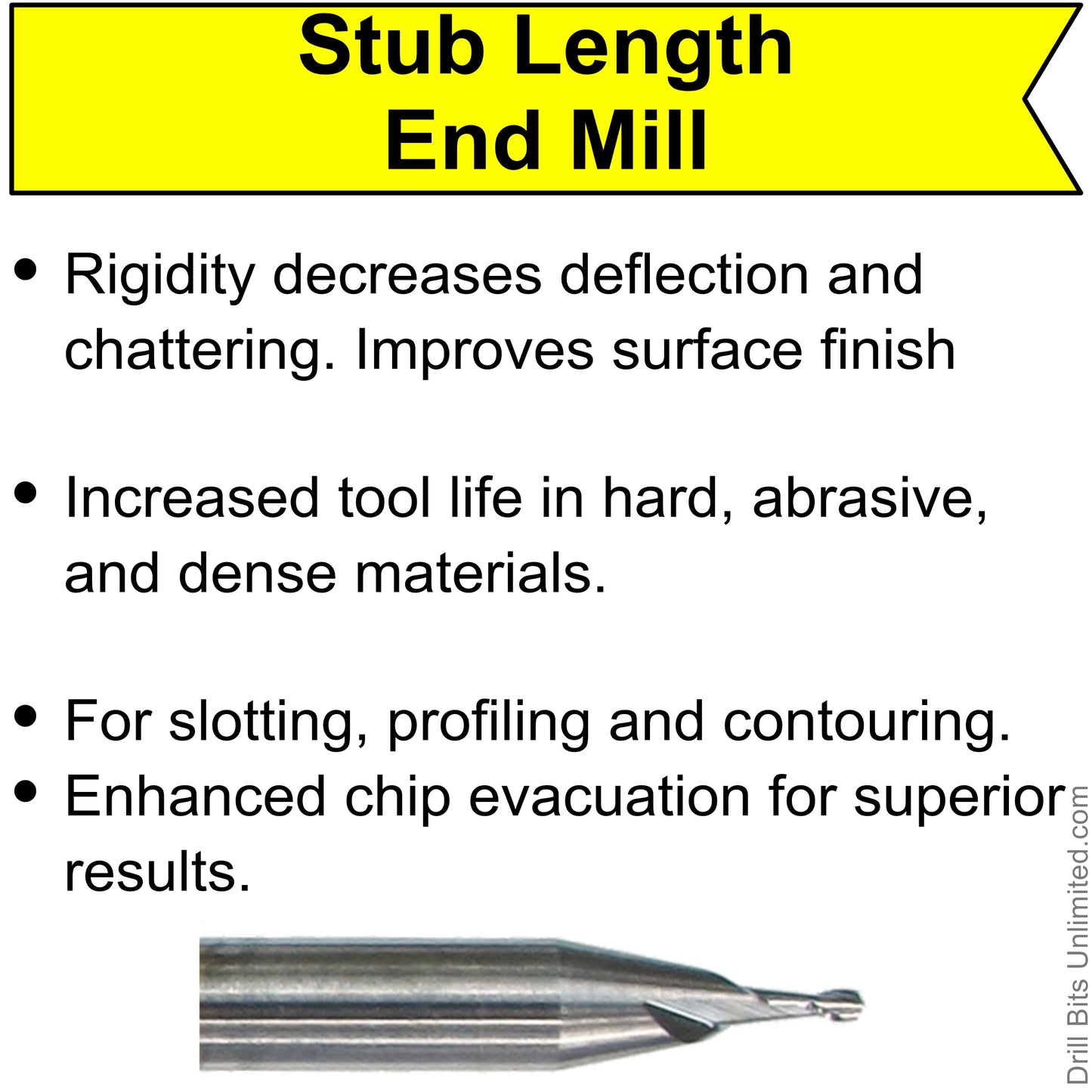

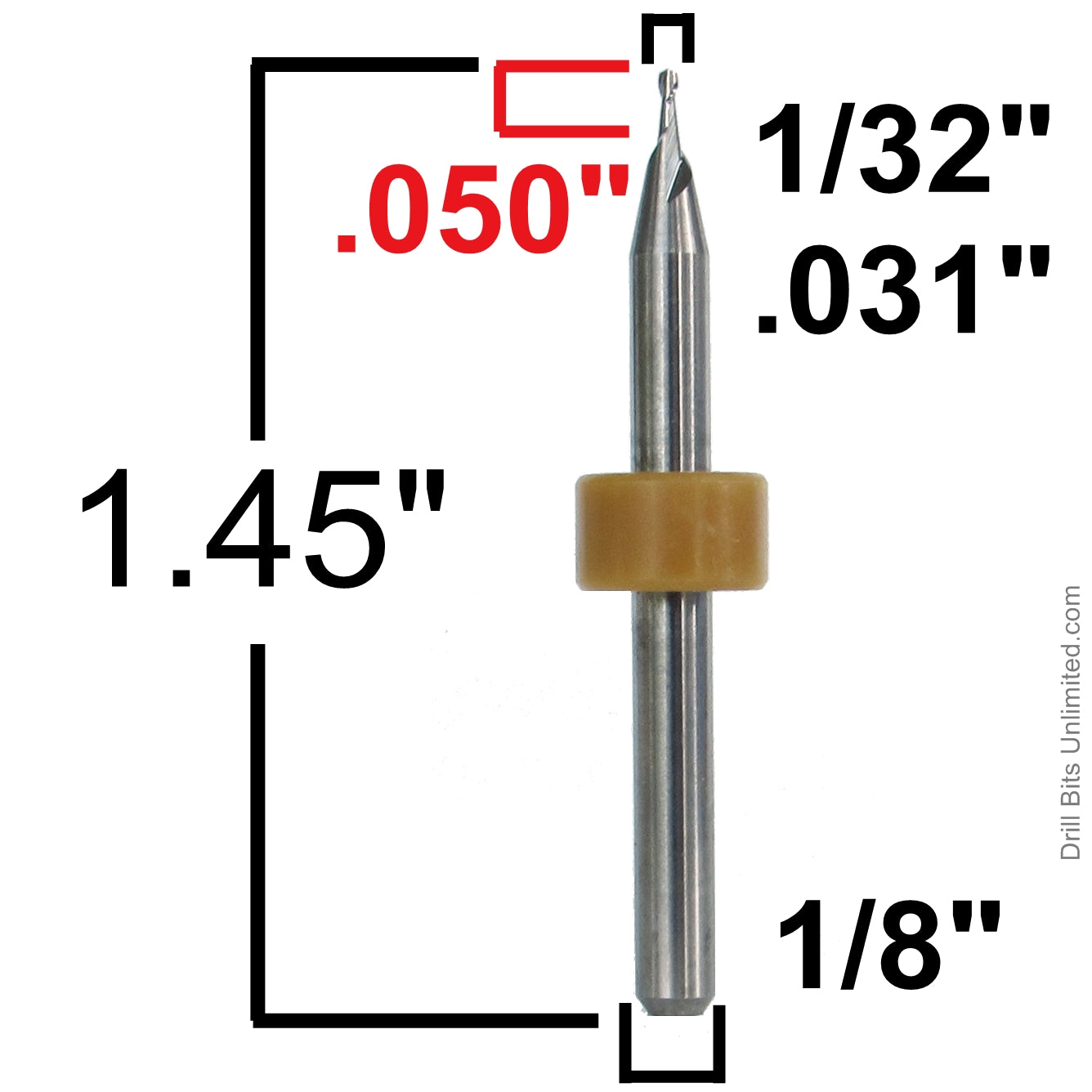

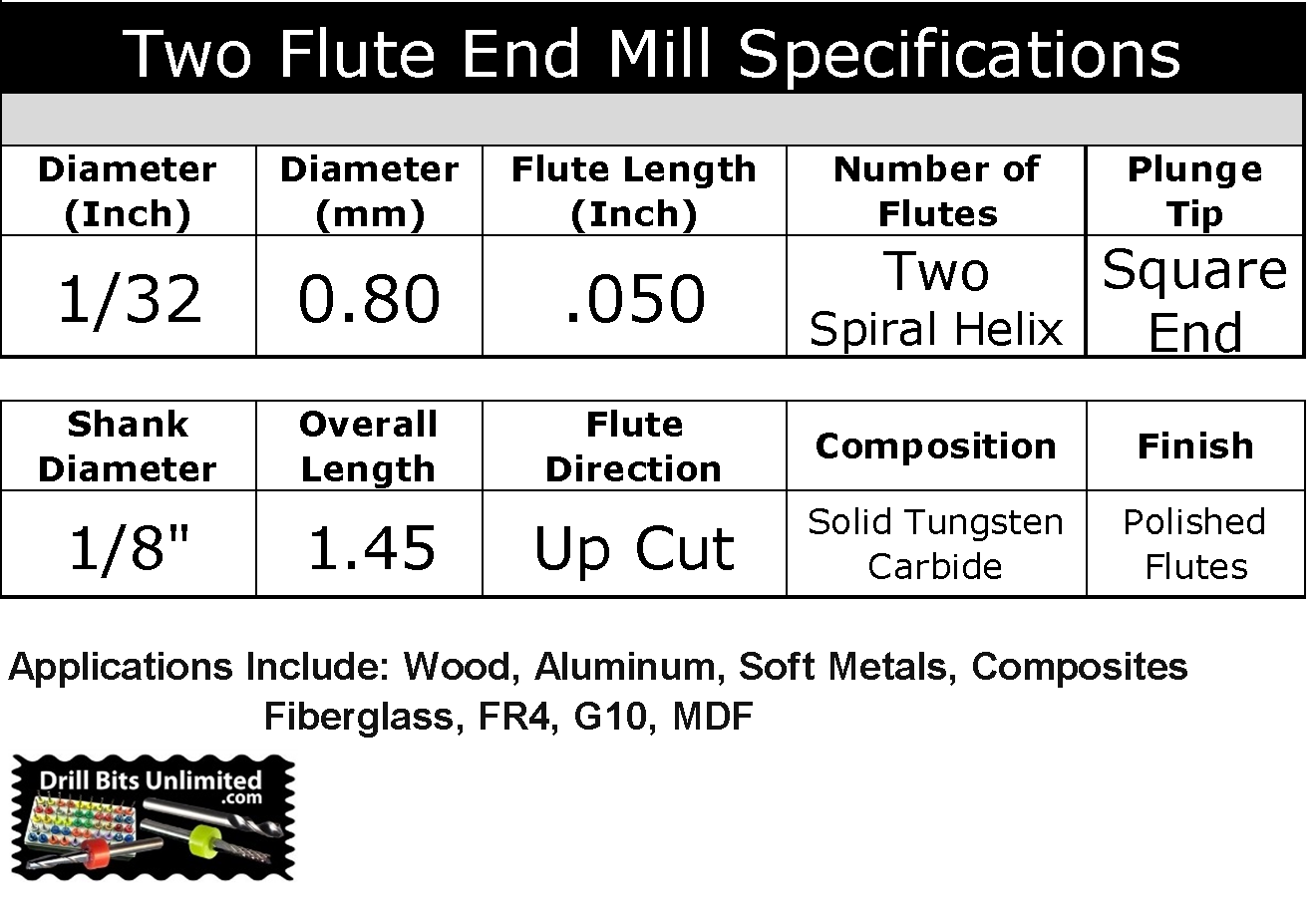

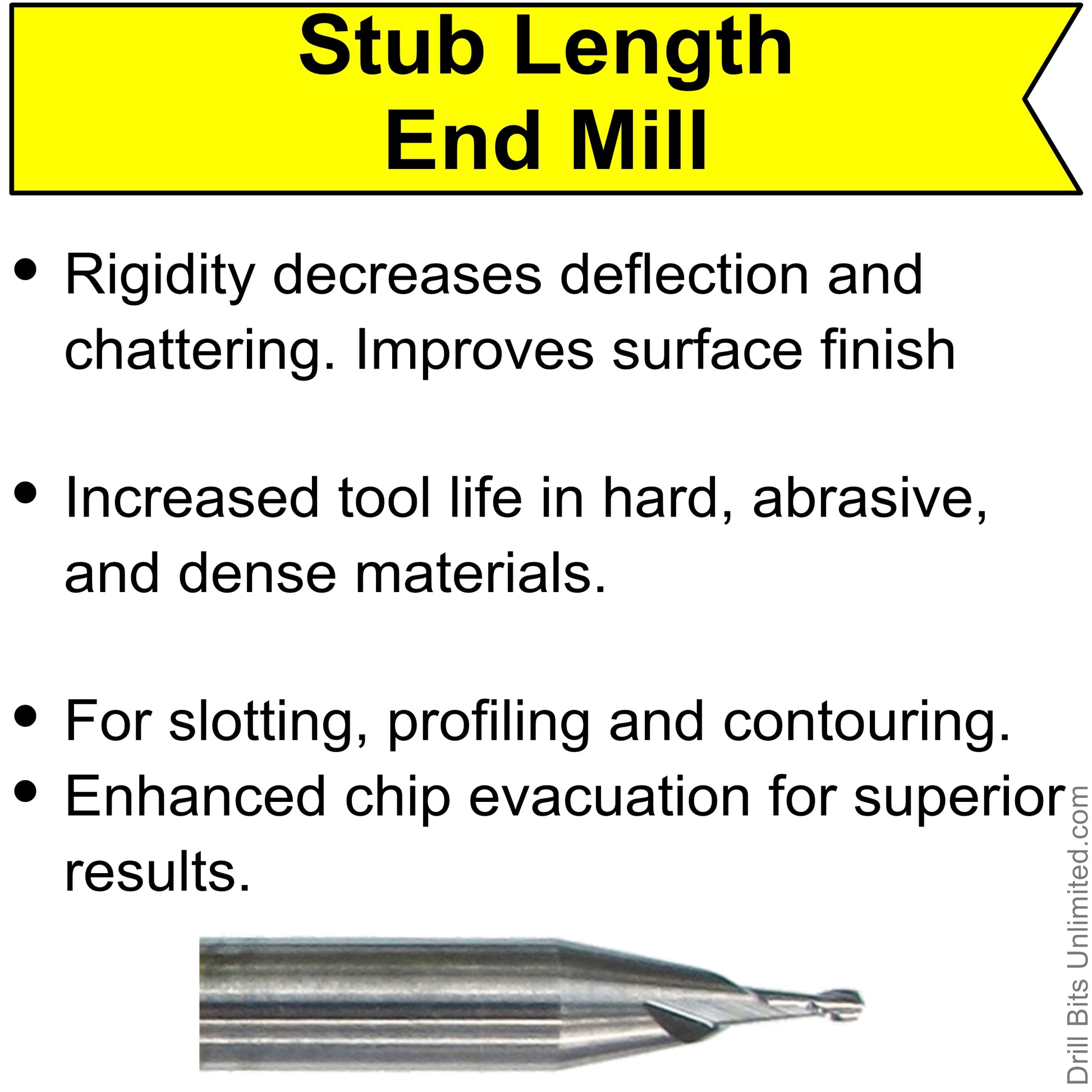

1/32" x .050" LOC STUB Length Two Flute Carbide End Mill - Up Cut Square End | Made in U.S.A. | M107ST

1/32" x .050" LOC STUB Length Two Flute Carbide End Mill - Up Cut Square End | Made in U.S.A. | M107ST

Regular price

$7.99 USD

Regular price

Sale price

$7.99 USD

Quantity

Couldn't load pickup availability

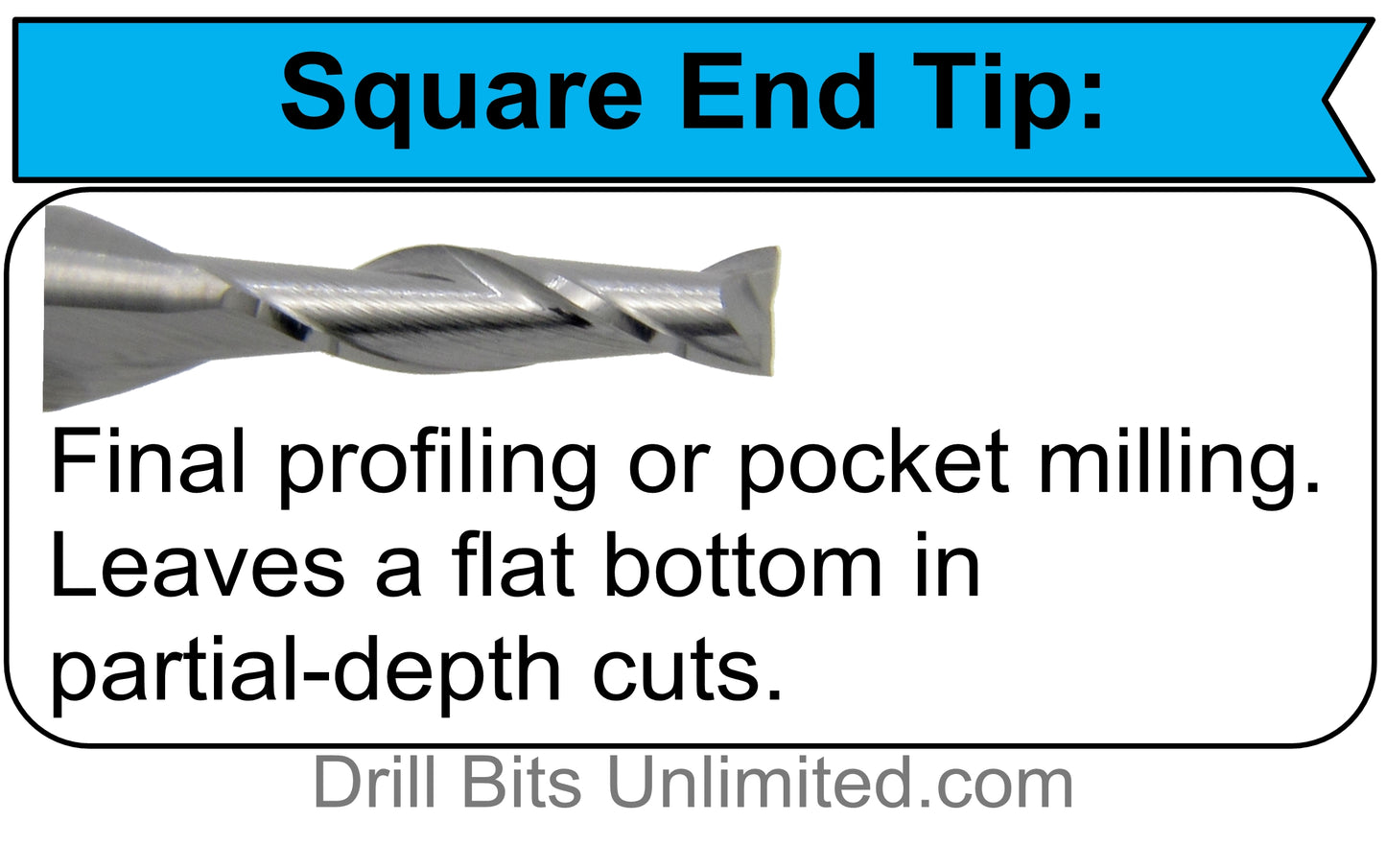

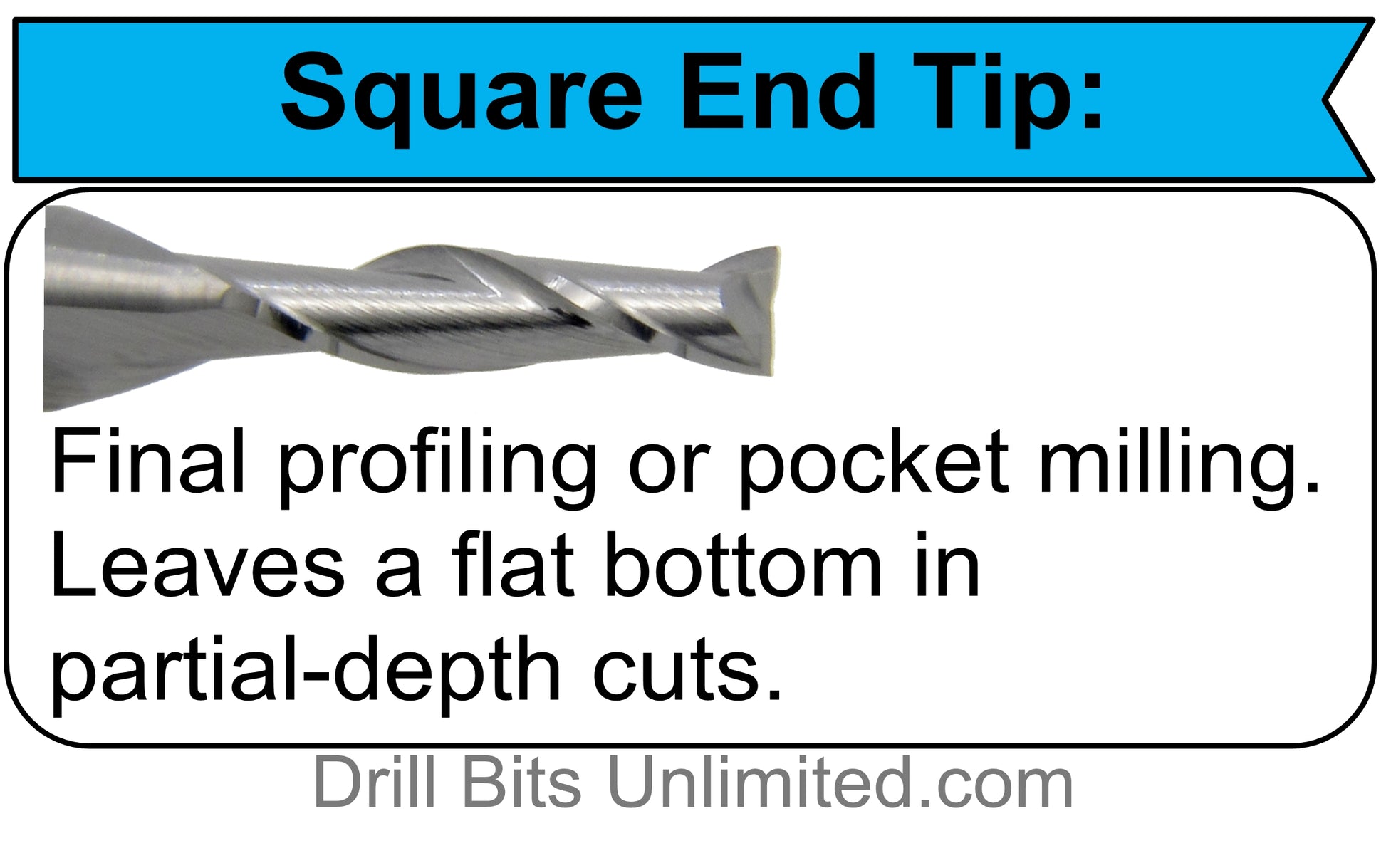

End style: Square End.

Share