Collection: Chamfer Mills / Reamers / Countersink

Chamfer Mills, Reamers & Countersinks

This collection includes three related finishing tool types used for edge-breaking, hole finishing, and screw seating. These tools can appear similar, so selection should be based on primary function — and for chamfers/countersinks, the included angle (°) is critical.

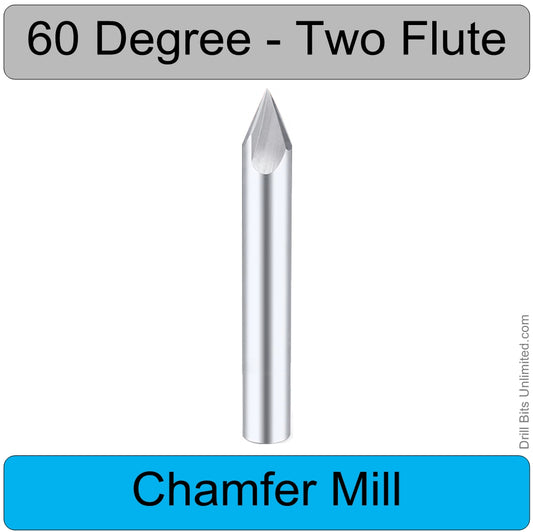

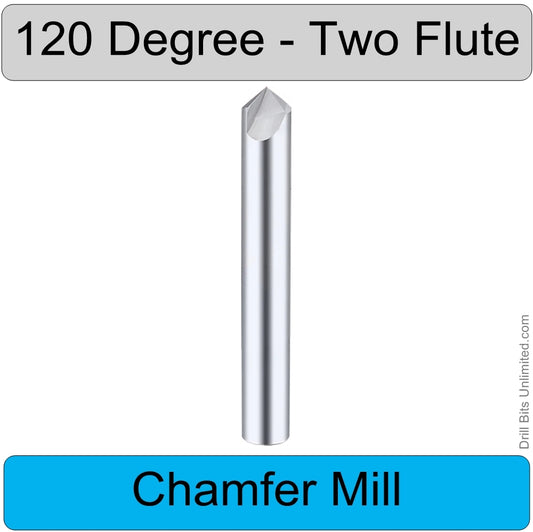

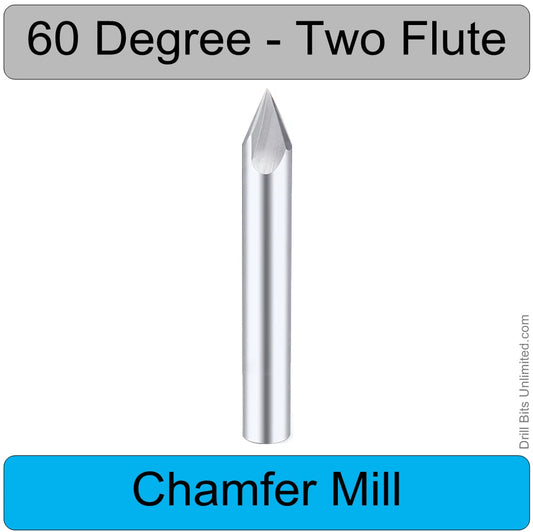

- Chamfer Mills: Versatile for chamfering edges, deburring, beveling, and creating lead-ins. Excellent for light edge-breaking, controlled chamfers, and often used interchangeably for countersinking in CNC applications.

- Countersinks: Designed to create a conical recess for flat-head screws to sit flush. Common angles: 82° (standard for imperial/US fasteners) and 90° (standard for metric fasteners).

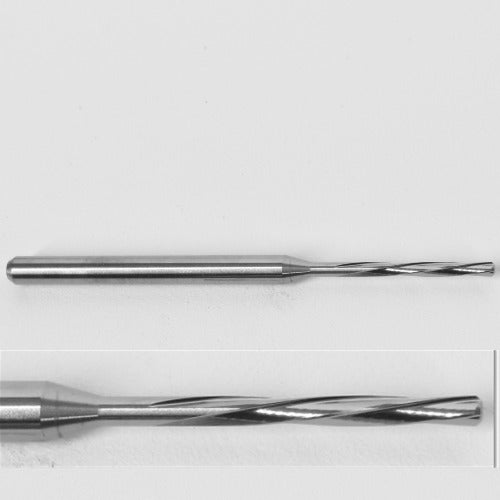

- Reamers: Used to enlarge a pre-drilled hole to a precise diameter with superior roundness, straightness, and surface finish (typically removing minimal material from an undersized hole).

How to Choose

- Need a screw head to sit flush? → Countersink; always match the angle exactly to the fastener (e.g., 82° for inch screws).

- Breaking sharp edges, deburring, or adding a general bevel? → Chamfer mill (angle controls chamfer size/profile).

- Need a highly accurate hole diameter and finish? → Reamer (primary spec is the final diameter).

Important Notes

- Angle (°) is critical for chamfer mills and countersinks — confirm it matches your application/fastener.

- For best results, use conservative feeds/speeds and avoid excessive dwell to minimize chatter and heat buildup (especially in plastics/softer metals).

- Pre-chamfer holes lightly before reaming for smoother entry.

-

1/4" .250" 82 Degree Carbide Countersink - 16 Flutes - 1/8" Shank - Made in USA

Regular price $34.95 USDRegular price -

1/8" (.125") 2-Flute 90 Degree Carbide Chamfer Mill Made in U.S.A. CM102

Regular price $11.95 USDRegular price -

60 Degree Chamfer Mill for deburring chamfering Slotting Spotting Carbide Two Flute CM105

Regular price $9.95 USDRegular price -

1/8" (.125") 4-Flute 90 Degree Carbide Chamfer Mill Made in U.S.A. CM101

Regular price $9.49 USDRegular price -

120 Degree Chamfer Mill for deburring chamfering Slotting Spotting Carbide Two Flute CM107

Regular price $9.95 USDRegular price -

0.39 mm Carbide Reamer K058

Regular price $54.95 USDRegular price -

90 Degree Chamfer Mill for deburring chamfering Slotting Spotting Carbide Two Flute CM106

Regular price $9.95 USDRegular price -

0.64 mm Carbide Reamer K226

Regular price $32.25 USDRegular price -

1.46 mm Carbide Reamer K026

Regular price $21.49 USDRegular price