Collection: Engraving Bits

Carbide Engraving Bits — Precision Detail & PCB Isolation Routing

Engraving bits (commonly called V-bits) are small-diameter carbide cutting tools designed for controlled-depth engraving, fine detail work, and selective material removal. They are widely used for lettering, scoring, inlays, and PCB trace isolation routing, where cut width is determined by depth rather than tool diameter.

These tools are suitable for CNC routers and precision milling machines working with materials such as FR-4 and G-10 laminates, fiberglass, carbon fiber composites, plastics, aluminum, brass, hardwoods, and other non-ferrous materials.

How Tip Angle Affects Engraving & PCB Isolation

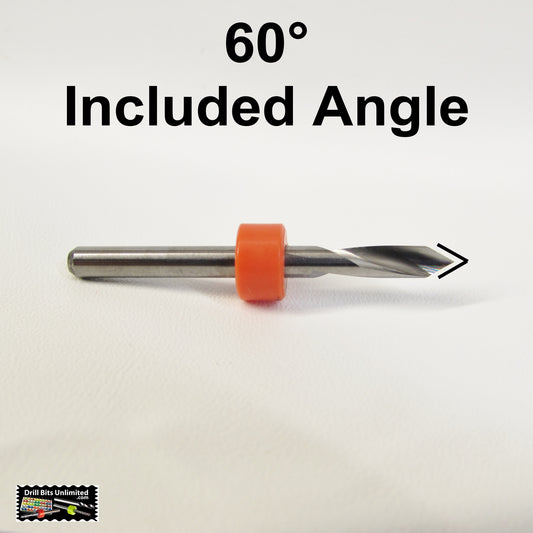

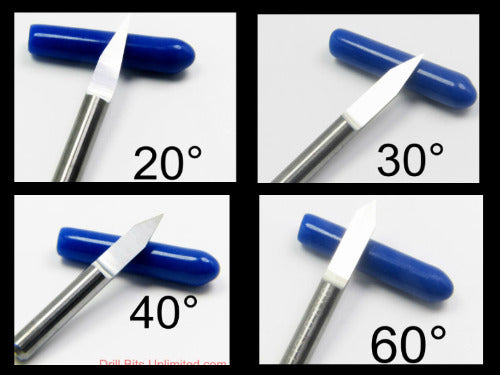

The included angle of an engraving bit directly controls cutting behavior:

- Smaller angles (10°–30°): Produce very fine lines and narrow isolation paths at shallow depths. Ideal for high-density PCB trace isolation and intricate detail work (requires careful depth control due to finer tips).

- 60°: A versatile, general-purpose angle commonly used for engraving, scoring, and reliable PCB isolation routing.

- 90°–100°: Stronger tips that produce wider grooves, suited for bolder engraving, deeper cuts, and applications where durability is prioritized.

PCB note: Because cut width depends on depth, consistent Z-height control, flat spoilboards, and secure workholding are essential for repeatable isolation results.

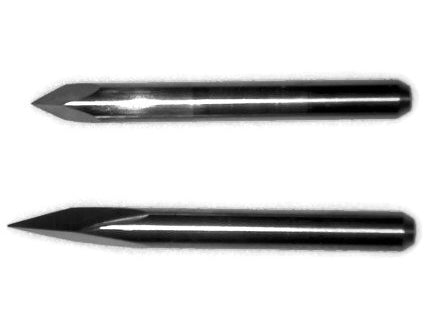

Engraver Geometry — V-Bit vs Pyramid Engravers

This collection includes two closely related styles of rotary carbide engravers:

- Standard V-Bit Engravers: Feature two cutting edges and a defined included angle (such as 30°, 60°, or 90°). These provide predictable groove width based on depth and are the preferred choice for PCB isolation routing, controlled-depth engraving, lettering, and fine line work.

- Pyramid (3-Edge) Engravers: Use a triangular, multi-faceted cutting tip with defined angles (commonly 30° or 60°). The three-edge geometry offers a stronger, more durable tip and improved chip evacuation, making these engravers well suited for intricate detail work or applications where standard V-bits may be more fragile.

For most precision engraving and PCB applications, standard V-bit engravers are recommended. Pyramid engravers are a good alternative when additional tip strength and durability are desired.

All engraving bits in this collection are manufactured from solid carbide for sharp cutting edges, long tool life, and consistent performance. Browse individual tools, multi-angle listings, and sets below to select the engraver that best matches your application and required level of detail.

-

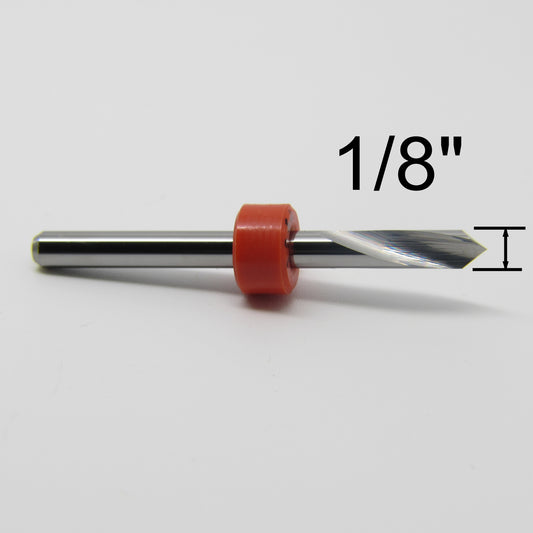

.030" 60 Degree, Scoring / Engraving, Trace Isolation V-Bit Engraver High Precision - Made in U.S.A. E102

Regular price $14.99 USDRegular price -

.0625" 1/16" 60 Degree, Scoring / Engraving, Trace Isolation V-Bit Engraver -High Precision Made in U.S.A. E104

Regular price $14.99 USDRegular price -

1/8" x 60 Degree, Scoring / Engraving, Trace Isolation V-Bit Engraver High Precision - Made in U.S.A. E107

Regular price $11.99 USDRegular price -

1/8" 3.175mm 100 Degree, Scoring / Engraving, Trace Isolation V-Bit Engraver High Precision - Made in U.S.A. E106

Regular price $11.99 USDRegular price -

4 Piece V-Engraver Set - 10, 15, 20, and 30 degree ENG-101

Regular price $9.72 USDRegular price -

4 Piece V-Bit Engraver Set - 20, 30, 40 and 60 degree ENG-102

Regular price $9.72 USDRegular price -

V Bit Carbide CNC Engraver 1/8" Shank 10, 15, 20, 30,45,60, or 90 Degrees

Regular price $3.99 USDRegular price -

3 Edge Pyramid Engraving Bits 1/8" Shank Pyramid Engravers - Solid Carbide 30/60 Degree

Regular price $4.99 USDRegular price -

15 Degree, 0.10mm Tip Titanium Coated Carbide V Engraver ENG15T

Regular price $4.89 USDRegular price -

Ten Piece V-Engraver Pyramid Engraver Variety Set ENG-SET1

Regular price $36.99 USDRegular price$40.80 USDSale price $36.99 USDSale