Collection: Straight Flute End Mills

Straight Flute End Mills feature parallel cutting edges that minimize upward or downward cutting forces during machining. This helps reduce material lifting, tear-out, and delamination in softer or layered materials such as wood, plastics, laminates, and composites.

Best used for:

- Wood, plastics, laminates, and composite materials

- Thin workpieces where clean edge quality matters

- Operations where spiral-induced thrust could distort the part

Why choose it

- Reduces upward or downward thrust compared to helical flutes

- Helps prevent lifting, chipping, and edge tear-out

- Works well in abrasive or brittle materials where straight cutting forces are preferred

Single- & O-Flute Guide — choosing the right option for plastics & soft materials

2-Flute vs 3+ Flute — when to use each

Use the filters below to narrow results by diameter, flute geometry, plunge tip type, and cut direction to find the exact tool you need.

-

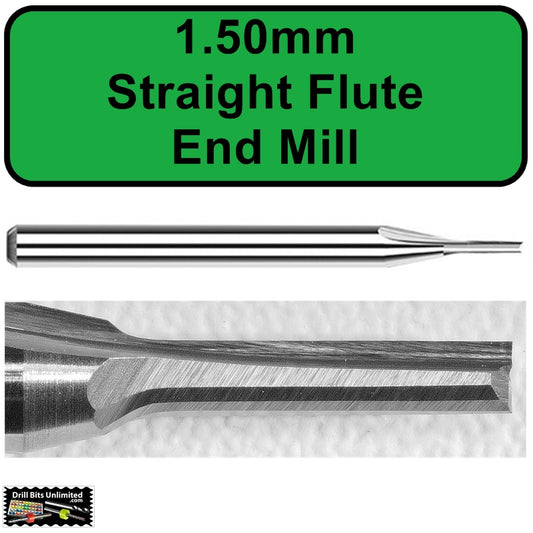

1.50 mm 2-Flute Straight Flute Carbide End Mill – For Wood, Plastic and Acrylic M234

Regular price $5.99 USDRegular price -

1.00 mm 2-Flute Straight Flute Carbide End Mill – For Wood, Plastic and Acrylic M233

Regular price $5.99 USDRegular price -

1/8″ 2-Flute Straight Flute Carbide End Mill – For Wood, Plastic and Acrylic M150

Regular price $5.99 USDRegular price -

Carbide End Mill M180

Regular price $9.76 USDRegular price